PRODUCT

BK-7008EBP-100120 Lithium Battery Pack Cycle Testing System

Model:BK-7008EBP-100120

Battery:EV Battery Pack 100V120A

Numbers of Channels:8 CH

Application:EV lithium battery pack cycle performance testing.

BK-7008EBP-100120 Lithium Battery Pack Testing System

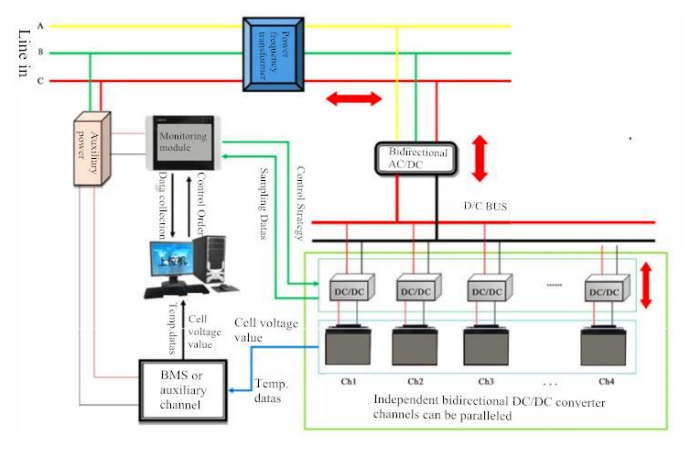

The SDCBUS series power battery performance testing system is a bidirectional single-channel, multi-channel high-precision AC and DC power processing system independently developed by Bluekey and controlled by a computer remote detection monitoring and processing platform. The system utilizes the bidirectional characteristics of power facilities (which can send and receive electrical energy) to meet the needs of one-way and two-way transmission of the load, thereby realizing the feeder control of the load's electrical energy.There is no resistive load power consumption during the feeding process, which reduces the energy loss caused by traditional resistive discharge. The product can be used to test the electrical performance of various types of lithium batteries, lead-acid batteries, special liquid batteries, etc., such as capacity test, cycle life test, working condition simulation test, overcharge and overdischarge tolerance test, etc.; At the same time, it can also be used for aging test of various electronic loads, such as aging test of chargers.

Battery pack capacity test

Battery pack charge/discharge characteristic test

Battery pack charge/discharge efficiency test

Battery charge retention and recovery ability test

Battery pack cycle life test, inter-channel cycle test

Battery pack temperature characteristic test

DC internal resistance test of battery pack

Battery pack pulse charge/discharge test

Battery pack working condition simulation test

Battery pack overcharge and overdischarge rate withstand capability test

3.System advantage

High efficiency to realize electric energy feedback to the grid

Adopt patented common DC bus topology, which can realize the power conversion between channels on the DC side

Adopt DSP+IGBT power control scheme to realize high-speed and precise control of electric energy

Wide margin and timely power control algorithm to ensure stable and reliable equipment operation

Configurable output voltage, current, power range, compatible with various types of batteries

15-year hardware design life of the whole machine (all equipment adopts imported IGBT and film capacitors to ensure product quality)

AC access adopts self-adaptive technology, no need to distinguish grid phase sequence

Advanced software phase-locked control technology, active rectification, inverter total emission harmonic THDI≤5%

Scan the code to automatically bind the test process file, scan the code to automatically start the test, automatically determine the unqualified battery, perform data retrieval between multiple computers in the local area network, and automatically synchronize the process file and other special functions to help the automation of battery production.

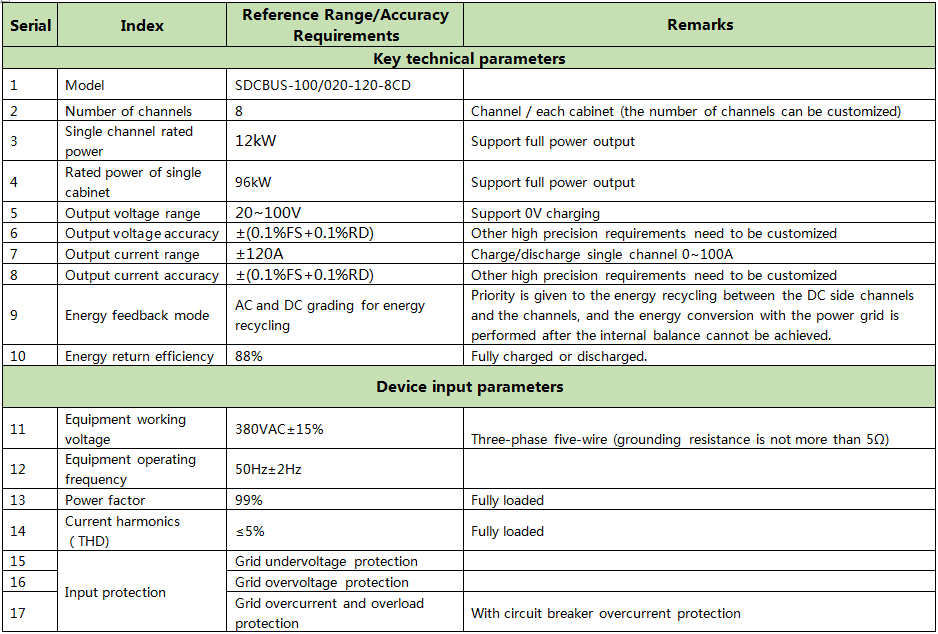

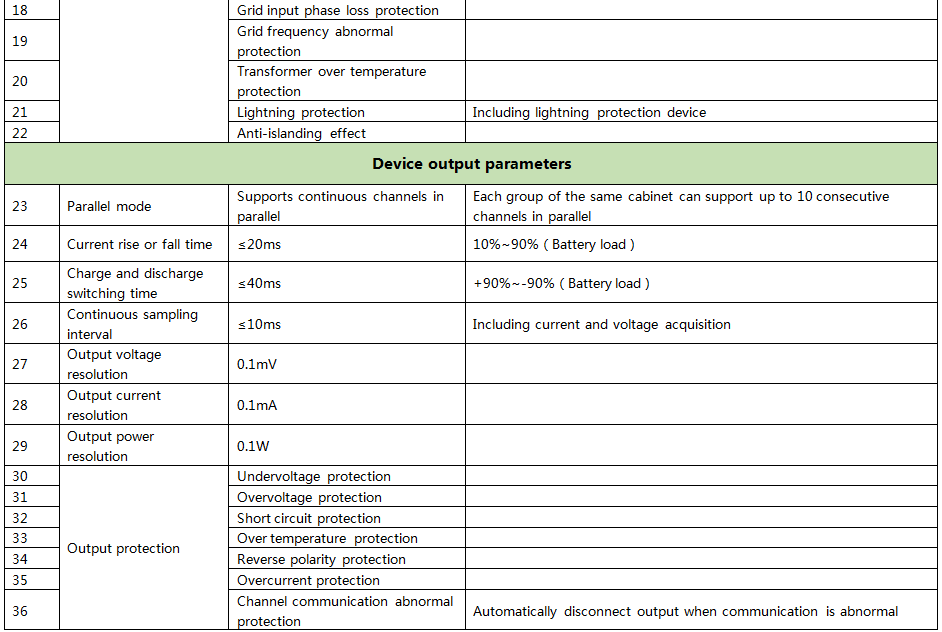

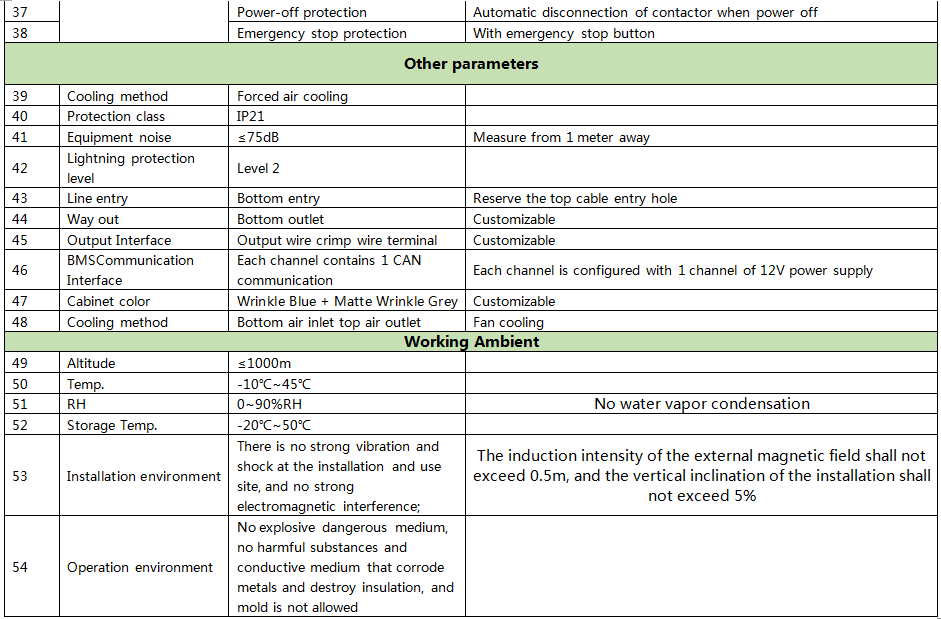

Ⅱ Equipment parameters

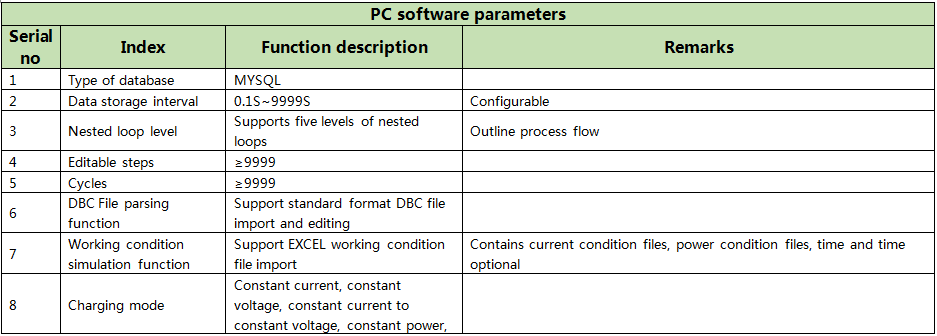

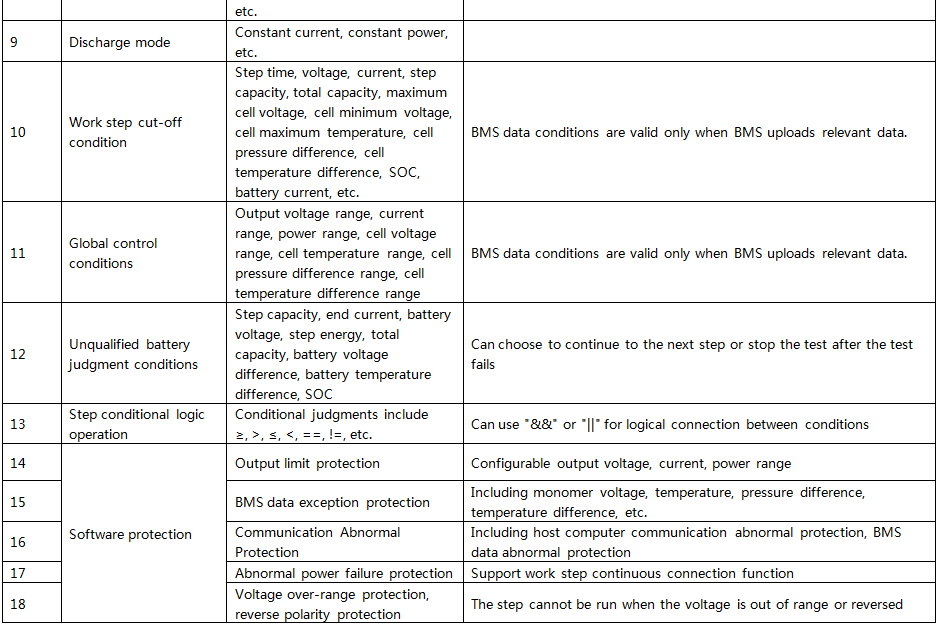

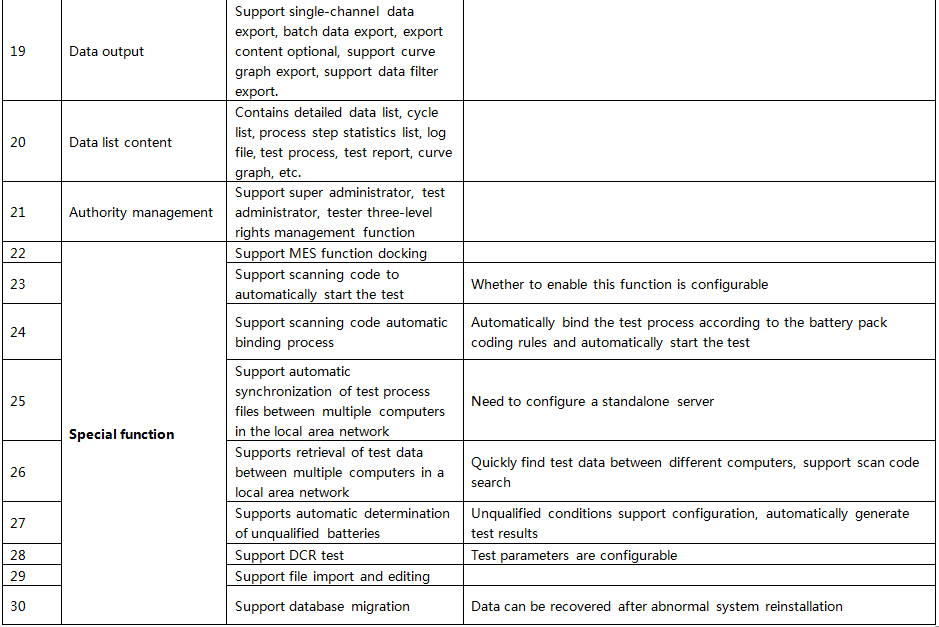

Ⅲ Software function