PRODUCT

BK-3256LP/5 5V5A Lithium Pouch Cell Charge Discharge FormationTesting & Grading Equipments Manufacturer from China

Model:BK-3256LP/5

Battery:Lithium Pouch Cell

Application:For lithium ion pouch battery cell charge discharge testing and capacity grading formation.

BK-3256LP/5 Solid-state lithium battery automatic testing and formation equipment

Model:BK-3256LP/5

Ⅰ.Basic structure of equipment:

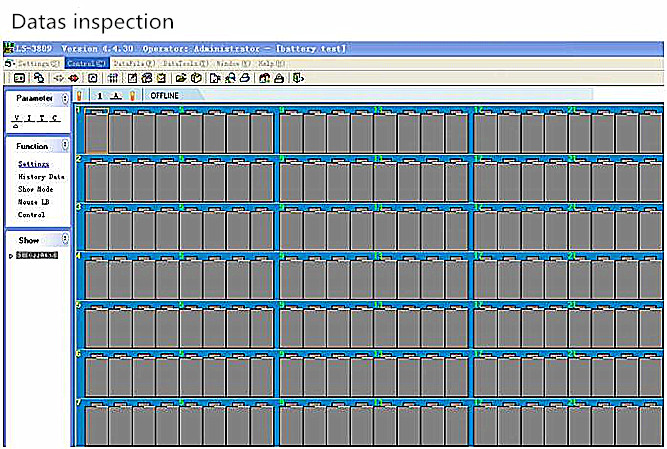

This equipment is mainly composed of a computer, a communication interface and a battery detection cabinet. The battery detection cabinet is composed of a fixture and a board for placing the fixture, a constant current and constant voltage source, a register control circuit, a sampling circuit, a single chip microcomputer and a control panel.

Ⅱ.Equipment main performance:

1.Each device can perform constant current and constant voltage charging and constant current discharge tests on 256 batteries that meet the voltage range.

2.The constant current-constant voltage power supply with invention patent is adopted, and the switch from constant current to constant voltage has no impact, which is especially suitable for the charging requirements of lithium-ion batteries.

3.The equipment adopts AVR single-chip computer as the control center and cooperates with the peripheral sampling circuit. It can be controlled by the upper-level computer. When connected to the computer, the complete charge and discharge curves of all channels can be saved, or it can be separated from the upper-level computer and operated through the control panel. Constant current and constant voltage charging, constant current discharge test, sorting by time, etc.

4.Each battery completely has an independent constant current and constant voltage source, which is self-contained and does not affect each other.

5.A light-emitting diode is installed on each battery fixture as a working status display. When the discharge is completed, it can be used to indicate battery capacity sorting.

6.Real-time detection of the voltage of each battery, when charging, first constant current charging, when the battery voltage reaches the set value, it will smoothly switch to constant voltage charging, when the set time or current termination conditions are met, the charging ends. During constant current discharge, when the battery voltage is lower than the set value, the discharge ends and the corresponding battery indicator lights up.

7.With power-down protection function, it can continue to run after the original work process is connected.

8.The power tube adopts 50N06, which is suitable for batteries that require lower discharge voltage, such as lithium iron phosphate batteries.

9.The upper computer can set 32 step parameters and 256 cycles, and each upper computer can be connected to 1-10 sets of single-chip microcomputer systems (5 sets are recommended).

10.Supporting software functions.

A.Graphical operation interface is used to display the battery voltage, current, time, capacity and other data, and the corresponding working status and abnormal conditions are displayed in various colors;

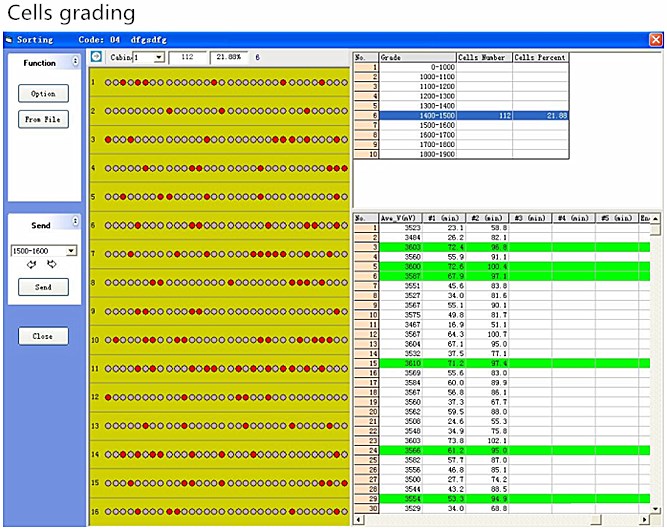

B.Any segment battery capacity indication (up to 100 segments);

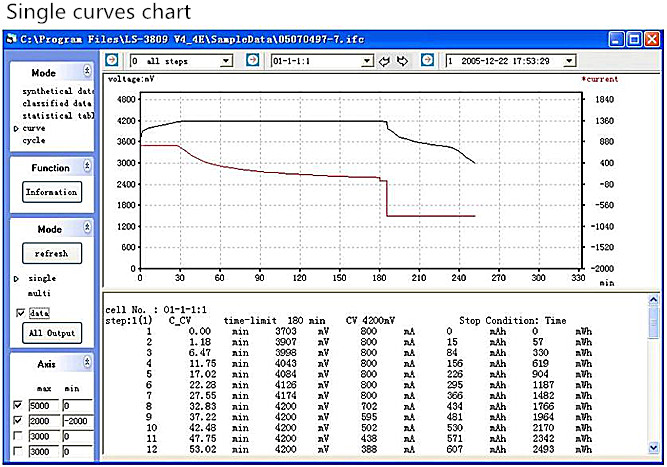

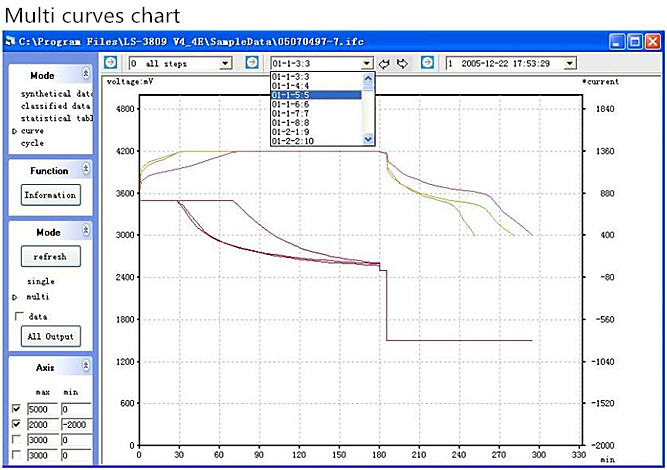

C.The data points can be recorded according to the changing conditions of voltage, current and time to form a complete charge and discharge curve data. The time interval of the curve data points is less than 8 seconds

D.Various conditions (capacity, time, open circuit voltage, discharge platform, etc.) for battery sorting function;

E.Automatic calculation of constant current charging ratio, capacity loss, discharge efficiency, average voltage, median voltage and other data;

F.Operator authority setting, hierarchical operation;

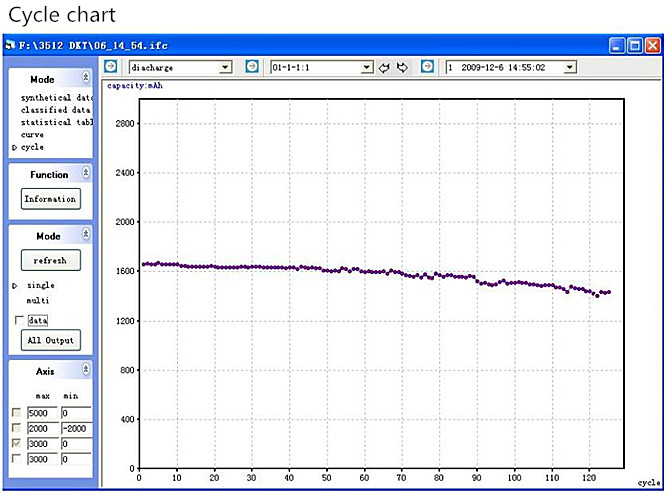

G.It can display charge and discharge curve diagram and cycle diagram;

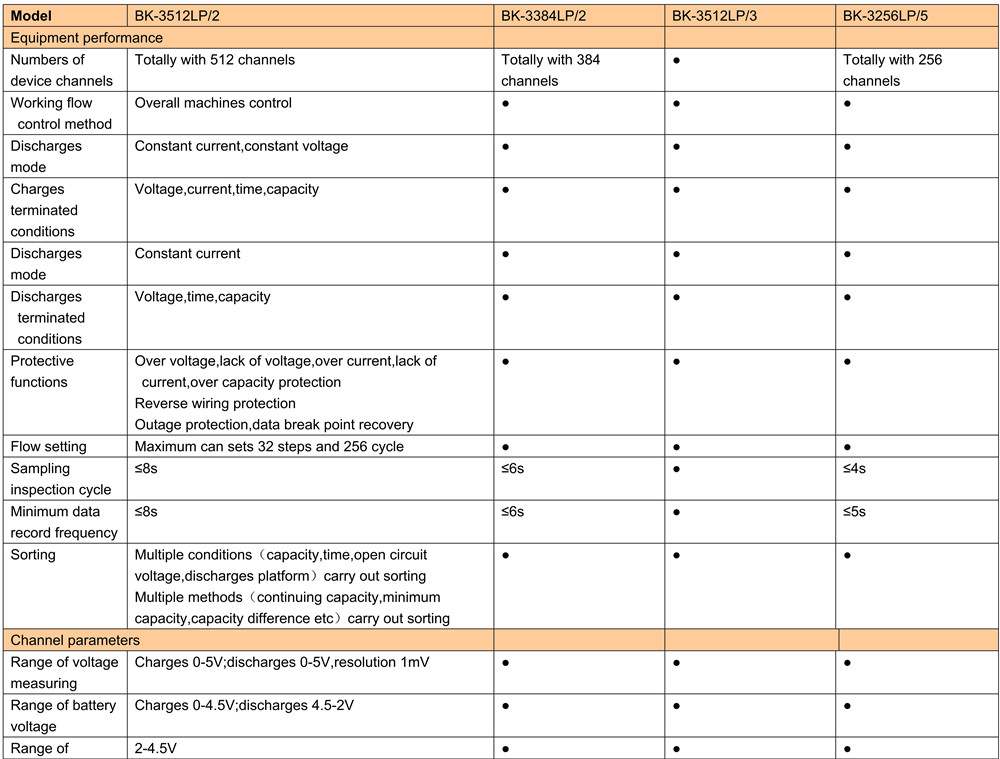

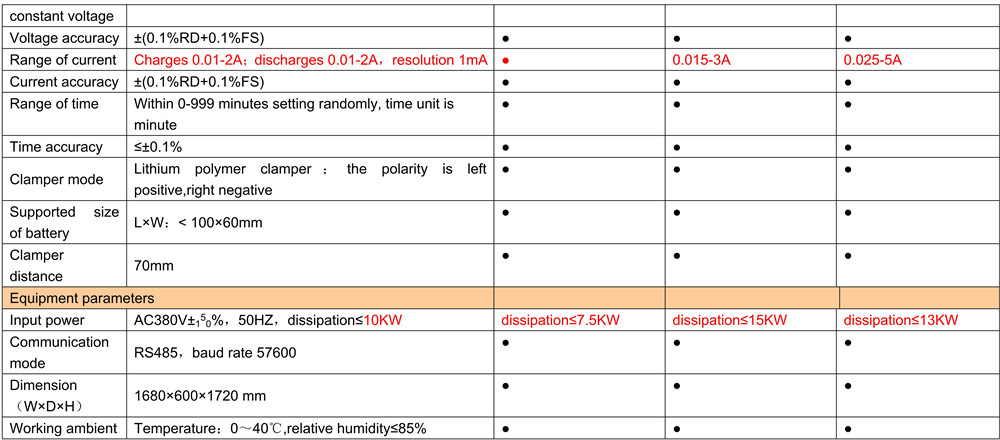

Ⅲ.Main technical parameters:

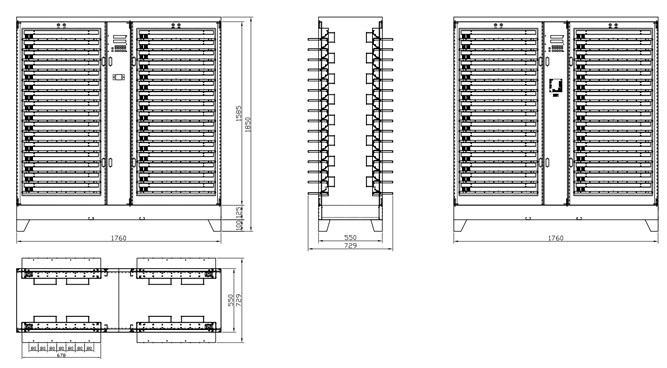

Ⅳ.Equipment outline drawing:

Ⅴ.Battery testing software screenshot: