PRODUCT

BK-8768L/3 Semi-Automatic Pin Tray Lithium ion Battery Cylindrical Cell Testing Equipments Manufacturer from China

BK-8768L/3 Lithium Cell Charge Discharge performance testing system special for testing 21700 Lithium Cylindrical cells

Current & Voltage:5V3A

Battery:Lithium ion cylindrical cells

Lithium ion Cell Semi-automatic formation and grading system

Model:BK-8768L/3

Ⅰ.Automatic Testing & Sorting System

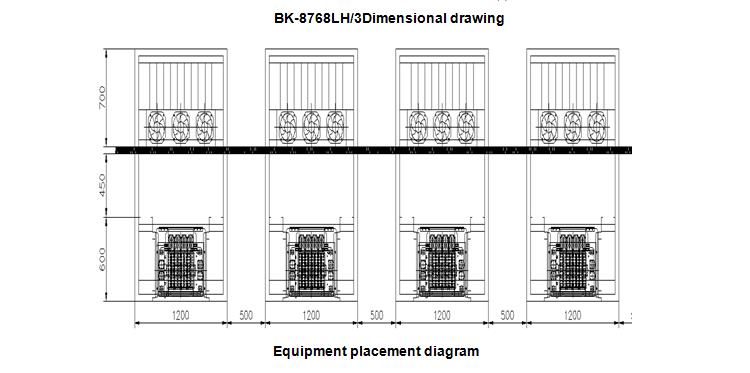

BK-8768LH/3 Battery Automatic Formation and Test Instrument,It is a high-precision needle bed type automatic testing equipment developed by our company for 18650 lithium-ion battery.。The device can be combined with BK-700-192N internal resistance automatic detection equipment and BK-9192N automatic sorting equipment to form a needle bed type automatic detection and sorting system suitable for 18650 lithium ion battery.,Complete battery formation, charge and discharge test, internal resistance test, sorting, etc.。The system can also be applied to batteries of other specifications according to the specifications and dimensions of the battery loaded on the tray. The structure of the system is as follows:

BK-8768LH/3Integrated design of control power supply and needle bed fixture for automation into inspection equipment,Clamping the battery through the tray by the pneumatic needle bed clamp。By setting the charge and discharge parameters,Charge and discharge test the battery,The test data is collected by the control computer (host computer) of the device.、Processing and saving,And save the tray data with the barcode of the battery tray as the file name.,Through the local area network,Transfer the pallet data to the specified shared path of the control computer of the sorter。Throughout the test sorting process,Battery tray is a carrier for transfer, storage and recording,The battery of the same tray is charged and discharged, and then sent to the internal resistance test equipment.,Test voltage and internal resistance,Test data is saved on both the internal resistance test control computer and the sorting control computer;Finally, the sorting machine sets the sorting level according to the capacity, time, open circuit voltage, average voltage, time to reach five specified voltages, internal resistance and the like through the sorting machine, and the battery is hierarchically selected by the ejecting mechanism.

*The latest version of the detection cabinet software for constant current and constant voltage charging steps,Add three parameters of “constant current time”, “constant current capacity” and “proportion” in the comprehensive data.,Increase the constant current charging ratio as the sorting parameter during sorting (need to be selected at the time of setting).

Ⅰ. Cells tray

1. 18650 dedicated battery tray,The battery is distributed in 12 rows and 16 columns in the tray,Each battery tray can hold 192 pcs of 18650 batteries。

The dimensions of the tray are as follows:

Ⅲ.BK-8768LH/3 Lithium Battery Automatic Test and Formation Equipment

1.Basic structure of equipment

This equipment is mainly composed of computer, control power supply and needle bed pneumatic clamp. The control power is composed of a constant current constant voltage source, a registration control circuit, a sampling circuit, a single chip microcomputer and a control panel. The pneumatic clamp is divided into 4 layers, each layer corresponding to 192 batteries, and each layer is independently operated by a button and a solenoid valve control jig.

2.Main performance of the equipment

1.Each device consists of 2 sets of single-chip control systems. The whole device can perform constant current and constant voltage charging and constant current discharge test on 768 single-cell lithium-ion batteries.

2.Control power supply and needle bed integrated design, the fixture adopts four layers of independent structure, a total of 4 sets of independent fixtures, each set can hold a tray. Each set of clamps is controlled by an independent solenoid valve to control the clamping of the battery. Each layer of fixtures is equipped with a safety linkage switch.

3.The tray can hold 192 18650 or 14500 and can be expanded to 96 26650 batteries. 4.he interior of the tray is compact and scientific in structure, fully utilizing battery cooling and ergonomics.

4.Equipment operating height: first layer: 330mm, second layer: 653mm, third layer: 976 mm, fourth layer: 1299 mm.

5.The battery heat dissipation adopts its own patented ventilation system to ensure that the ambient temperature of 768 batteries is balanced and not affected by the power supply.

6.One independent probe module for every 48 channels, easy to disassemble and easy to maintain.

7.With distributed system design, each 16 channels form a subsystem, the subsystem is embedded in the CPU, AD and DA circuits, and the total control CPU is connected through the communication line. The system structure is more reasonable and more convenient for maintenance.

8.With online upgrade function, you can send upgrade instructions through the computer to control the online upgrade program of the lower computer, which is convenient for long-term maintenance and upgrade of the equipment.

9.Adopt advanced constant current source technology, constant current to constant voltage switching without impact, especially suitable for lithium ion battery charging requirements.

10.Each battery has a completely independent constant current and constant voltage power supply, and the self-forming loop does not affect each other.

11.Using four-wire method fixture measurement, each battery has its own independent constant current and constant voltage power supply, and the self-forming circuit does not affect each other.

12.The fixture uses an eight-probe structure (dual current, dual voltage probe, four positive and negative probes) to ensure good contact with the battery.

13.Using 16-bit high-precision A/D converter, the current and voltage sampling resolutions are 0.1mA and 0.1mV respectively.

14.Each channel is equipped with a separate 16-bit D/A circuit with current and voltage regulation resolutions of 0.1 mA and 0.1 mV, respectively.

15.Each channel's current and voltage samples are converted by precision instrumentation amplifiers for higher test accuracy and better long-term stability.

16.Using the current automatic fine-tuning technology, when the sampling current deviates from the set value, the output current is automatically fine-tuned to ensure the current setting accuracy within the full-scale range.

17.Current and voltage calibration uses a programmable memory to save the calibration coefficient instead of the potentiometer adjustment, avoiding the fluctuation of the voltage and current values caused by the potentiometer adjusting the contact change, which is beneficial to ensure the accuracy of the device.

18.With a dedicated automatic calibrator, the calibration of the device is automatically realized by the computer-controlled automatic calibrator to collect the data of each channel. All the data is automatically saved in the computer, and the periodic calibration of the device is very easy.

19.Real-time detection of each battery voltage, when charging, first constant current charging, when the battery voltage reaches the set value, immediately switch to constant voltage charging, when the set time or current termination condition is met, the charging ends. At the time of constant current discharge, when the battery voltage is lower than the set value, the discharge is terminated.

20.Temperature correction function with battery capacity. The system collects the ambient temperature of each layer of battery, and can correct the battery discharge capacity at different ambient temperatures according to the temperature correction factor input by the user, and the capacity test is more accurate.

21.With data power-down protection function, the power continues to run.

22.The upper computer can set up to 32 steps and 256 cycles. Each set of upper computer can be connected to 1-8 sets of single chip microcomputer system.

23.The software is powerful and easy to operate. It can realize centralized measurement and control, data processing and report making functions of the device, and has various protection functions such as voltage abnormal protection, current abnormal protection, over capacity protection, constant voltage charging voltage fluctuation protection, etc. .

24.With quick start function, the bar code scanner can be used to directly scan the barcode on the device and the battery tray. The system will automatically recognize and work according to the preset detection process to reduce the operation.

25.At the same time, the test results are saved and processed in the machine and the sorting machine. There are various battery inspection interfaces to save the complete charge and discharge curve of each battery. The data is automatically stored in the device's own format, and the save curve and time interval are automatically determined.

26.It can be combined with BK-700-192N automatic internal resistance test equipment and BK-9192N automatic sorting equipment to form a lithium ion battery automatic sorting system. According to capacity, time, open circuit voltage, platform time, internal resistance, ΔV and other parameters. Perform battery

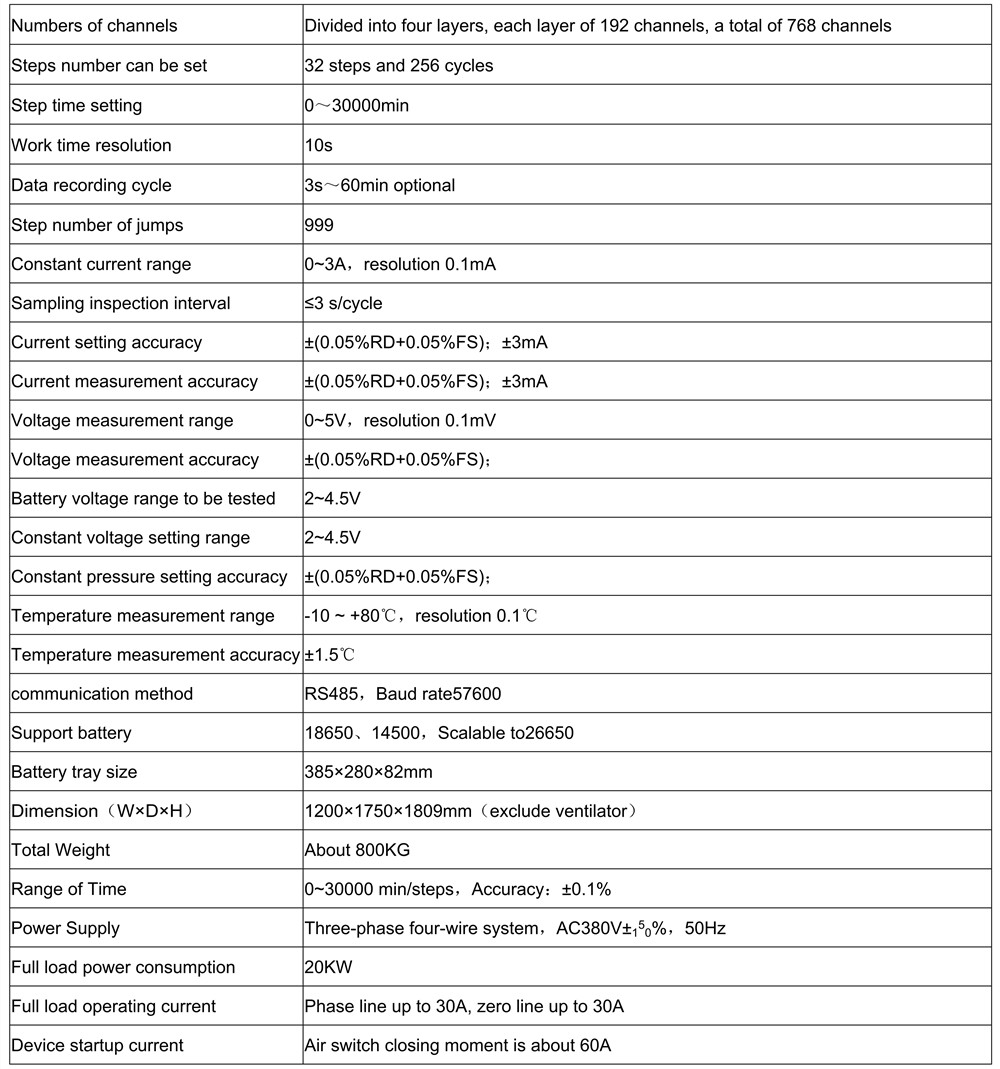

3.Main Specifications

Ⅰ.Equipment reliability assurance measures

1.Installation indicator tower light, used to indicate the working status, the operator can clearly understand the working condition of the equipment from a distance.

2.With contactor protection function, when a leakage current is abnormal at a certain point, the contactor moves, cuts off the power supply of the switching power supply, and automatically opens the clamp to ensure the safety of personnel, battery and equipment.

3.The equipment is equipped with an emergency stop switch. When an abnormality occurs, press the emergency stop switch to cut off the power supply of the switching power supply to ensure the safety of personnel, batteries and equipment.

4.Monitor the CPU operating temperature of the device and the ambient temperature of each layer of the battery, and set the normal operating temperature range. When the range is exceeded, an alarm is output.

5.Install a cooling fan for each layer of fixture to optimize the battery working environment.

6.Use a variety of isolation techniques in the line design to minimize interference.

7.Modular design, the equipment is composed of several standard modules, each constant current constant voltage source is independent, easy to replace and repair.

8.Turn into and distribute the probes of each layer of the cabinet, and measure the temperature evenly. The temperature measurement range is -10 ~ +80 °C, and the temperature resolution is 0.1 °C. Each layer of smoke sensor is formed into a volumetric cabinet to ensure stable operation of the equipment.

Ⅱ.System main configuration requirements

1.It is recommended that the user be equipped with UPS power for each computer to prevent damage to the computer or data in the event of a power outage.

2.The fixture part of the equipment is controlled by pneumatic components. The user needs to equip the air source, and the air source is required to be clean and dry, the air pipe interface is 1/2", and the air pressure requirement is >6Kgf/cm2.

3.When the device starts up, the instantaneous current is large. When the user configures the incoming power switch for the device, it is necessary to consider that the operating current of the power switch is not lower than the starting current of the device to avoid switching tripping. 3. When the device starts up, the instantaneous current is large. When the user configures the incoming power switch for the device, it is necessary to consider that the operating current of the power switch is not lower than the starting current of the device to avoid switching tripping.

4.The data exchange of the detection equipment, the sorting machine and the internal resistance machine is transmitted through the local area network, and the user needs to arrange the network line according to the placement position of the computer in the field.

5.Computer system configuration: computer system minimum configuration: CPU frequency above 2.0GHz, more than 1G memory, 500G hard disk space, LCD display, Windows 7 operating system, one available RS232 communication port, 10/100M network card, CD-ROM one, A mouse, a printer supported by Windows, etc. Each computer is equipped with a UPS power supply to prevent damage to the computer or data in the event of a power outage.

6.When the device starts up, the instantaneous current is large. When the demander configures the incoming power switch for the device, it is necessary to consider that the operating current of the power switch is not lower than the starting current of the device to avoid switching tripping.