PRODUCT

BK-3096E/60 5V60A EV LFP Lithium Prismatic Cell Charge Diacharge Formation Equipments

Model:BK-3096E/60

Battery:5V60A LFP LiFePo4 EV Prismatic Battery Cell

Number of Channels:96 CH

Application:EV prismatic cell charge discharge performance testing and formation testing.

BK-3096E/60 5V60A Energy Regenerate Lithium Battery Prismatic Cell Automatic Testing Formation Equipment

Techincal Profile

BK-3096E/60 DKJ energy regenerative lithium battery automatic testing and formation equipment technical specification (motor down pressure fixture type)

Ⅰ.Basic structure of BK-3096E/60 DKJ equipment

BK-3096E/60 DKJ energy-saving power lithium battery automatic testing and formation equipment consists of three parts: energy-saving testing power supply, motor pressing fixture and computer. The testing power supply adopts a modular structure and a control method of the whole machine, which can carry out formation, classification and parameter testing of lithium-ion power batteries, and is especially suitable for mass formation production and sorting of lithium-ion power batteries.

Ⅱ.Structural characteristics of the equipment

The equipment adopts an integrated structure, and the energy-saving testing power supply and fixture cabinet adopt an independent design overall structure. On the basis of ensuring that the detection power supply and the fixture cabinet are completely independent, the maximum possible effective use of space and the reduction of the length of external connection cables.

The appearance of the whole machine is shown in the figure below:

1.In the equipment structure, the energy-saving testing power supply is a completely independent box, and the control part in the power box adopts a modular design, and each independent power control box corresponds to 8 batteries. There are 12 power boxes in the whole machine.

2. The whole equipment is divided into two sides, A/B, with 48 batteries each. A/B side is equipped with 6 layers of battery trays. Each tray can place 8 batteries, which is convenient for manual battery loading and connection fixtures. The whole device can clamp a total of 96 batteries (8 pcs/tray*12 trays) not larger than the specification requirements at the same time.

Ⅲ.The main performance indicators of the equipment (in terms of supporting hardware)

1.Each equipment is controlled independently. This equipment is a master-slave rechargeable battery integrated measurement and control system composed of a microcomputer and a single-chip microcomputer. It has a modular single-sided structure. The entire cabinet can automatically test 96 batteries that meet the battery voltage range, including the single lithium ion that meets the voltage range. The battery performs constant current, constant voltage charging and constant current discharge control and testing.

2.This equipment is mainly composed of a computer, a communication interface and an automatic battery testing cabinet. The battery testing cabinet is composed of a constant current and constant voltage source, a register control circuit, a sampling circuit, a single-chip computer, a control panel and a fixture connection terminal.

3.The control mode of the whole machine, in conjunction with the supplier's single-point sorting system, can carry out formation, classification and parameter testing of rechargeable lithium-ion power batteries, which is especially suitable for mass formation production and sorting of lithium-ion power batteries.

4.The equipment adopts AVR single-chip computer as the control center, cooperates with the peripheral sampling circuit, and is controlled by the upper-level computer to complete constant current and constant voltage charging, constant current discharge test and constant power discharge.

5.Each battery completely has an independent constant current and constant voltage power supply, which is self-contained and does not affect each other.

6.Adopt advanced anti-current impact technology to realize no current impact during charging in all channels, no matter whether charging jumps to discharge or discharge jumps to charging, there is no current impact. At the same time, combined with the invention patented constant current-constant voltage power supply technology, it realizes a smooth transition from constant current to constant voltage switching without impact (no current spikes, no current breakpoints), etc.

7.It adopts 24-bit high-precision AD and 24-bit DA circuit, which has higher test accuracy.

8.The round needle four-wire method is used for measurement, which eliminates wiring and contact errors to the greatest extent. Both current and voltage sampling are differentially converted by precise instrument amplifiers, which have higher test accuracy and better long-term stability.

9.Using current automatic fine-tuning technology, when the sampling current deviates from the set value, the output current is automatically fine-tuned to ensure the current setting accuracy within the full range.

10.A special automatic calibrator is optional (the buyer needs to order separately). The calibration of the equipment is automatically realized by the computer-controlled automatic calibrator to collect the data of each channel. All the data are automatically saved in the computer. The regular calibration of the equipment is very easy.

11. Distributed system design is adopted. Each constant current box forms a single-chip microcomputer subsystem and is connected to the main CPU through a communication line. The modular design is easy to maintain. It has the function of data power failure protection and keeps running with electric energy.

12. Each channel of the device has an independent overcharge and overdischarge protection function. The hardware protection response speed of overcharge and overdischarge is ≤50ms, and the software alarm response time is about 1s. There is an alarm function in unexpected situations. With battery reverse connection, hardware protection function

Ⅳ. The main performance indicators of the equipment (supporting software)

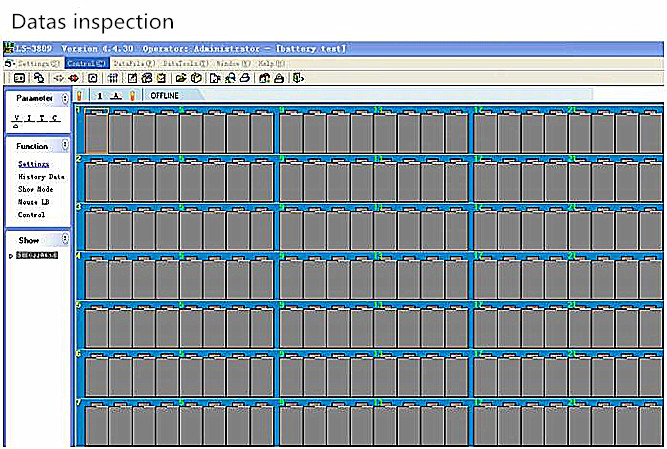

1.Graphical operation interface is used to display the voltage, current, time, capacity and other data of each battery, and the corresponding working status and abnormal conditions are displayed in various colors.

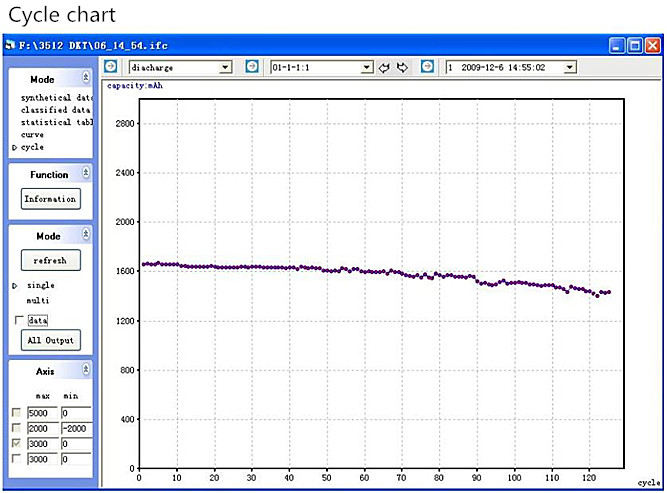

2.Data points can be recorded according to the changing conditions of voltage, current and time to form a complete charging and discharging curve data. The minimum recording time of curve data points is about 4 seconds (limited by the "tracking communication time" of the host computer).

3.It has a variety of hardware protection functions, including sampling line disconnection protection, upper and lower limit voltage overvoltage protection, and leakage protection.

4.The software is powerful and easy to operate. It can realize functions such as centralized measurement and control of equipment, data processing and report making, and has various protection and alarm functions such as voltage abnormalities, current abnormalities, over-capacity, and constant voltage charging voltage fluctuations. Each formed cabinet is equipped with a three-section alarm indicator.

5.With data power failure protection function. That is, in the event of an unexpected power failure or power failure, it can ensure that the battery is not impacted by reverse current. The function of saving running data, the battery will resume running according to the original procedure after a call, and the data can be connected.

6.The upper computer can set up to 32 steps and 256 cycles, and can display the cycle life curve. Each set of upper computer can be connected to 1 to 8 sets of single-chip microcomputer systems.

7. With the testing process confidentiality function, each operator can only use the process set by himself through a password.

8.Save the test results and perform data processing:

A.The software has a variety of battery inspection interfaces and inspection interfaces. The test results and data processing are stored in the equipment and the sorting machine, and the complete charge and discharge data and curves of each battery can be saved. It can record voltage, current, time, capacity and other data, has powerful data processing functions, and provides multiple curve modes. The software can freely export the collected chemical conversion or detection data, and the data export can be converted into Excel, Word, Access or text file format. The data is automatically stored in the device's own format, and the saving curve and time interval are automatically determined.

B.Any segment battery capacity indication (up to 100 segments).

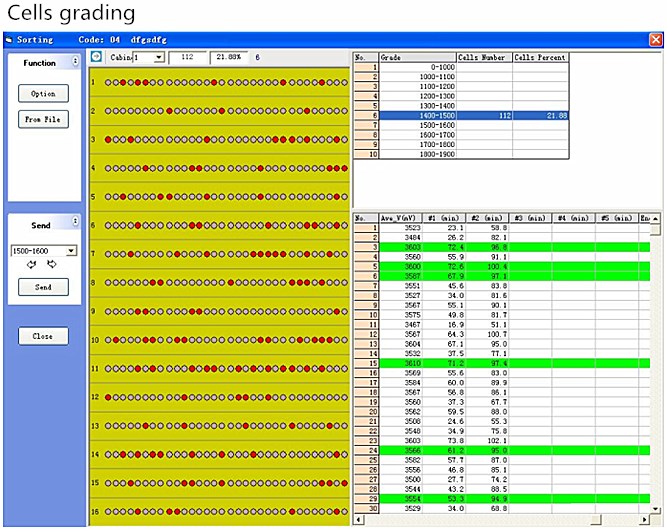

C.With the sorting system, battery sorting can be carried out according to various conditions (capacity, time, open circuit voltage, discharge platform, etc.).

D.Provide capacity statistics function.

E.Automatic calculation of constant current charging ratio, capacity loss, discharge efficiency, average voltage, median voltage and other data.

F.It can display charge and discharge curve graph, cycle life graph, etc.

G.When the computer crashes or shuts down unexpectedly and loses control of the formation cabinet, the formation cabinet must have upper and lower voltage protection functions; save the characteristic point data when offline.

H.It has an external data input interface, such as a bar code recognition device.

I. With remote online upgrade function. There is no need to replace the program chip when the software of the device's lower computer (main control single-chip) is upgraded.The online upgrade program of the lower computer can be controlled by sending the upgrade instruction through the computer, which is convenient for the update of the lower computer program of the equipment.

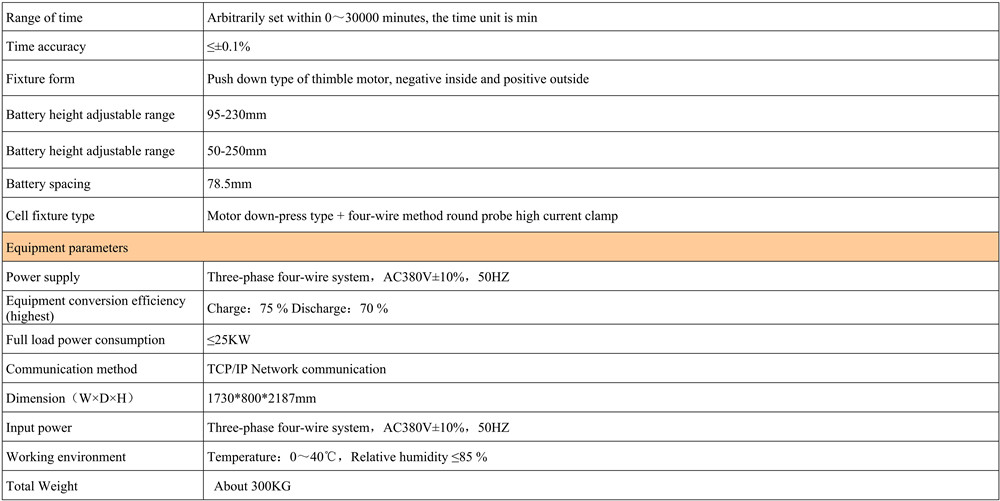

Ⅴ.Main technical parameters and performance of the equipment

Ⅵ.Screenshot of battery testing software interface and curve: