PRODUCT

BK-6802HV/60 120V60A EV Lithium Battery Pack Performance Cycle Performance Testing Equipments China

Model:BK-6802HV/60

Battery:120V60A EV Power Pack

Application:ev lithium battery power pack charge discharge cycler

BK-6802HV/60 120V60A EV Lithium Battery Group Cycle Lifetime Performance Tester

Model:BK-6802HV/60 (120V60A)

Ⅰ.Machine main performance:

1.Design and produce for performance testing and cyclelife testing of rechargeable battery group,suitable for R&D dept.Can detect lithium ion batteries that meet voltage requirements.

2.Designed and manufactured in strict accordance with national testing standards,All electrical performance test items for lithium-ion batteries in the standard can be tested。

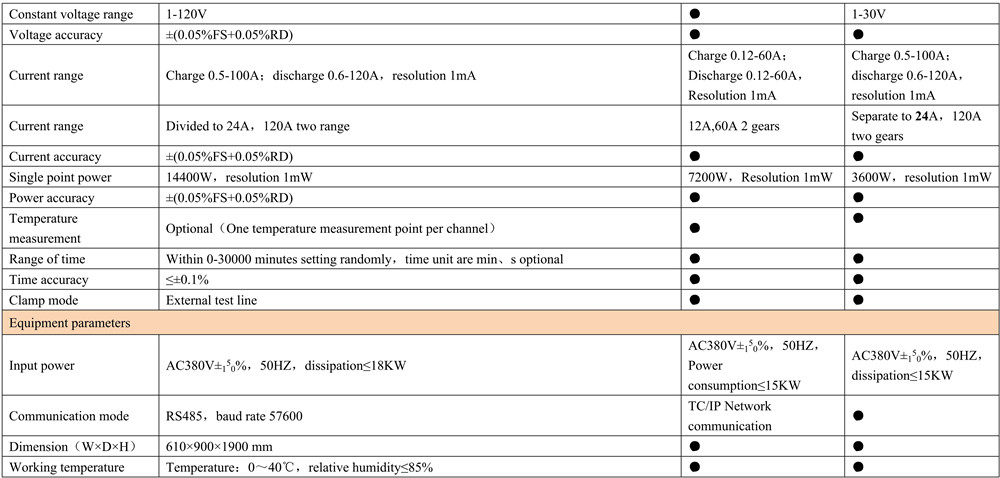

3.The device is divided into 1 set of CPU design. There are 8 constant current sources, which are controlled independently by 8 single-chip microcomputers. The charging and discharging process, charging and discharging current and constant voltage value are programmed by the computer separately.

4.With a variety of test modes, it can achieve constant current and constant voltage charging, constant power charging, constant power discharging and constant resistance discharging.

5.Modular design and manufacture, long-term operation is reliable and stable, easy to maintain.

6.Four-wire method for maximum elimination of wiring and contact errors, high test accuracy.

7.Adopt automatic current feedback adjustment technology to overcome the nonlinear factors of automatic current setting and ensure current setting accuracy in the full range.

8.16-bit high-precision A/D converter with independent 16-bit D/A circuitry for high current and voltage sampling and regulation.

9.The current and voltage are divided into two levels: high and low, which can guarantee the accuracy within the range.

10.With data power-down protection.

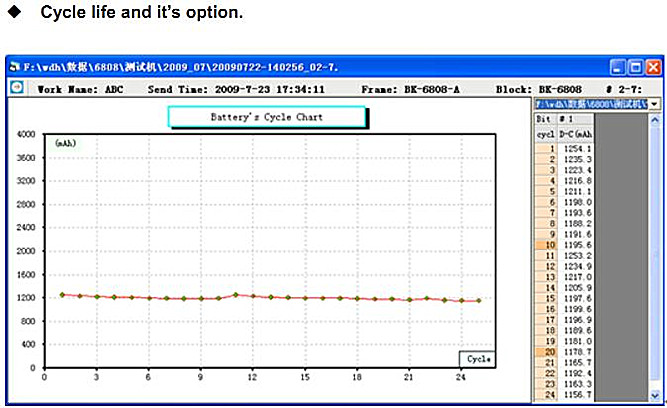

11.The host computer can set up to 64 steps and 9999 cycles to display the cycle life curve.

12.Each set of upper computer can be connected to 1-16 sets of single chip system.

13.Supporting software features:

A.It realizes functions such as centralized measurement and control, data processing and report making of equipment, and has various protection functions such as voltage abnormal protection and current abnormal protection.

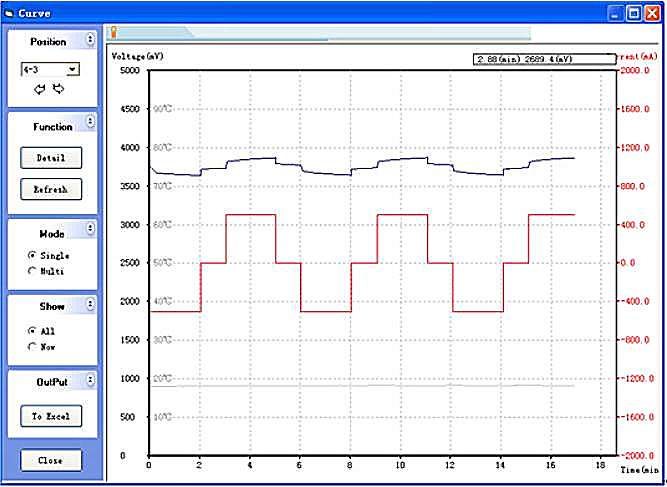

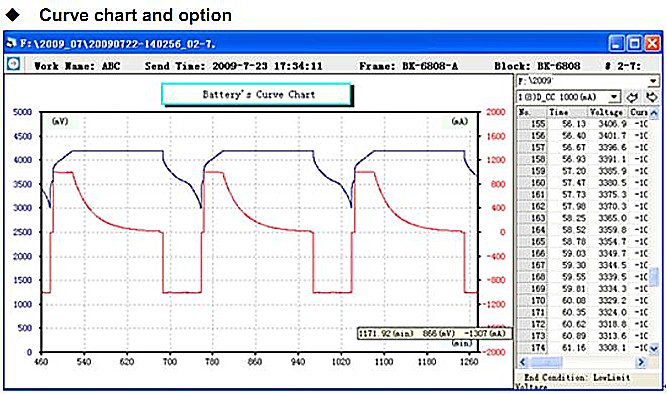

B.Provides powerful processing data functions, providing a variety of curve modes, such as voltage-time, current-time, internal resistance-time and its superposition curve, eigenvalues, cycle diagrams, etc., providing flexible programming options for easy use.

C.Data export function to export test data to Excel, Word, Access or text files;

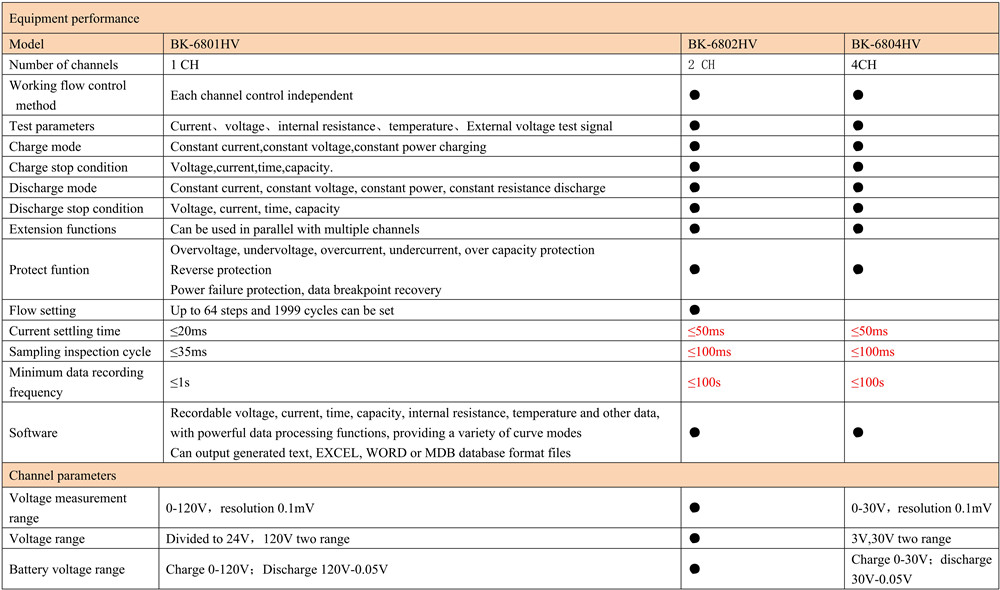

Ⅱ.The main technical parameters

Ⅲ.Energy-saving principle block diagram of equipment:

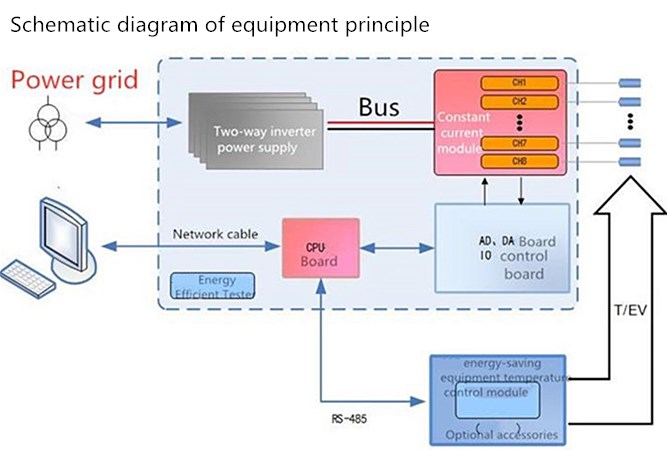

When charging:

●Charging adopts switching constant current source, which has higher energy conversion efficiency than traditional linear constant current source;

●Energy flow direction: (power grid + energy generated by discharge equipment) → AC/DC two-way inverter power supply → constant current source module → battery

When discharging:

●Energy flow direction during discharge: battery→constant current source module→AC/DC two-way inverter power supply→battery→(discharging equipment + grid)

When discharging, most of the energy will flow through the factory's AC bus to the charging equipment and other energy-consuming equipment (such as air conditioning, lighting, office equipment, etc.), and there is still excess energy that will be fed back to the grid.

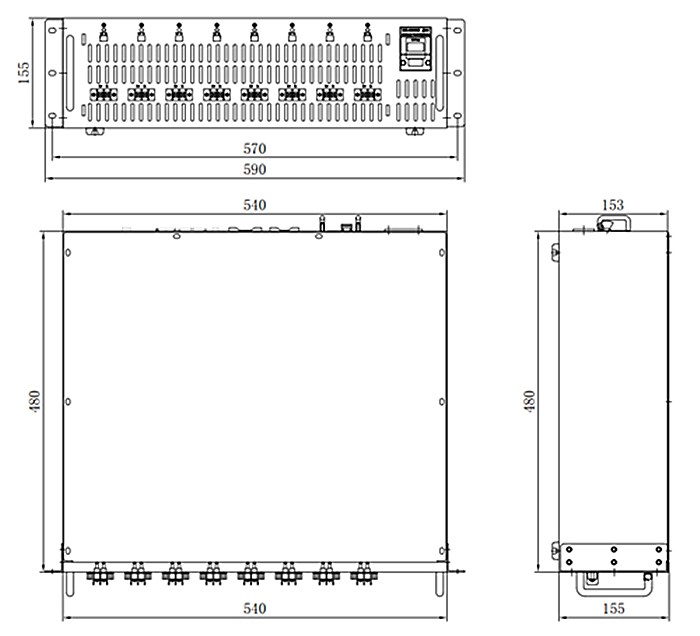

Ⅳ.Equipment drawing:

Ⅴ. Screenshot of battery testing software interface and curve: